Safety valve รุ่น SV9 สามารถ Set Pressure ได้ 0.5 – 13 bar หากสั่งซื้อกับทางร้าน จะมีบริการเซ็ตให้ฟรี พร้อมเทสรั่ว เทสเพรสเชอร์ และตอกค่าที่เซ็ตลงในเนมเพลท โดยไม่มีค่าใช้จ่ายใดๆทั้งสิ้นครับ

Description

- The SV9 is a cast steel safety valve suitable for use on Steam

- Typical applications : The SV9 is suitable for the protection of steam boilers, pipelines and pressure vessels, general process industry applications

How it works

Body Design Conditions

- The Safety officiate prevent the pressure on the system than is required. The need to adjustment the hardness of the spring to fit the pressure used.

- Safe working pressure of the plant it protects and the valve must achieve its rated capacity with an overpressure of no more than 10%

| SV9-16 | SV9-40 | |

| PMO Maximum operating presspure | 16 bar | 40 bar |

| TMO Maximum operating temperature | 300 °C | 300 °C |

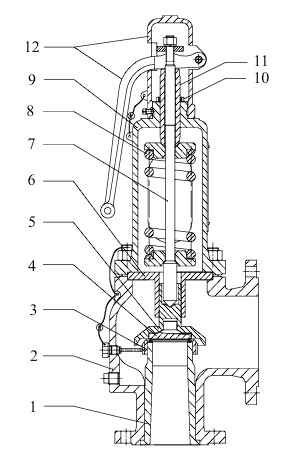

Materials

| No. | Parts | Materials |

| 1 | Nozzle | Stainless steel |

| 2 | Body | Cast steel ASTM A-216 WCB |

| 3 | Adjusting Ring | Stainless steel A276-96 |

| 4 | Disc | Stainless steel |

| 5 | Disc Holder | Stainless steel A276-96 |

| 6 | Guide | Stainless steel A276-96 |

| 7 | Stem | Stainless steel A276-96 |

| 8 | Spring | Carbon steel 50CrVA |

| 9 | Spring housing bonnet | Cast steel ASTM A-216 WCB |

| 10 | Lock nut | Cast steel |

| 11 | Spring adjusting screwed | Cast steel |

| 12 | Cop and lever | Cast steel ASTM A-216 WCB |

Dimensions (mm)

| Size | DN | D | K | Z-Ød | DN | D1 | K1 | Z-Ød1 | L | L1 | Weight (kg.) |

| DN20x32 | 20 | 105 | 75 | 4-14 | 32 | 140 | 100 | 4-18 | 85 | 95 | 10 |

| DN25x40 | 25 | 115 | 85 | 4-14 | 40 | 150 | 110 | 4-18 | 100 | 105 | 12 |

| DN32x50 | 32 | 140 | 100 | 4-18 | 50 | 165 | 125 | 4-18 | 110 | 115 | 15 |

| DN40x65 | 40 | 150 | 110 | 4-18 | 65 | 185 | 145 | 4-18 | 115 | 140 | 21 |

| DN50x80 | 50 | 165 | 125 | 4-18 | 80 | 200 | 160 | 8-18 | 120 | 150 | 28 |

| DN65x100 | 65 | 185 | 145 | 4-18 | 100 | 220 | 180 | 8-18 | 140 | 170 | 48 |

| DN80x125 | 80 | 200 | 160 | 8-18 | 125 | 250 | 210 | 8-18 | 160 | 195 | 61 |

| DN100x150 | 100 | 220 | 180 | 8-18 | 150 | 285 | 240 | 8-22 | 180 | 220 | 84 |

| DN125x200 | 125 | 250 | 210 | 8-18 | 200 | 340 | 295 | 12-22 | 200 | 250 | 98 |

| DN150x250 | 150 | 285 | 240 | 8-22 | 250 | 405 | 355 | 12-26 | 225 | 285 | 168 |

Installation

- The valve should always be mounted vertically upwards with its main axis vertical.

- The valve should be fitted to the pipe work or vessel by means of the shortest possible length of pipe or fitting.

- There should be no intervening valve or fitting i.e. it should not be possible to isolate the safety valve.

- The inlet pipe connection should not be smaller than the valve.

- The outlet pipe size should be equal or larger than the valve outlet to keep backpressure below 10% of the set pressure.

- Direct the outlet pipe work to the safe point of discharge where there is no risk of injury to persons or damage to property in the event of the valve operating.

- The outlet pipe work should be adequately supported such that it does not place undue stress on the safety valve.

Reviews

There are no reviews yet.